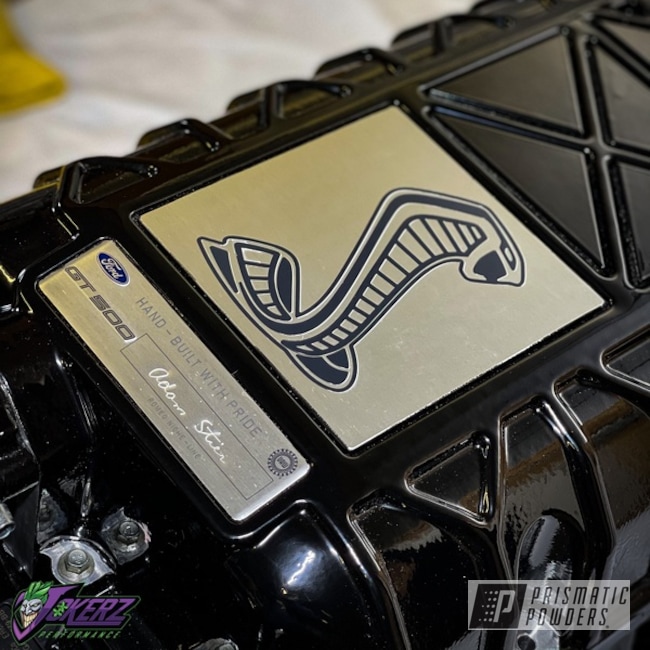

INK BLACK

Item: PSS-0106

In Stock (Ships in 1-2 Business Days)

We are temporarily out of this product.

Description:

Ink Black is a gloss black, polyester solid tone with a mirror-like finish.

Gloss Units: 85+

WARNING: This product may expose you to chemicals known to the State of California to cause cancer. For more information, see the product's safety data sheet.

Product Collections

What does this match?

Product Support

Have questions about this product?

Ask A QuestionQuestion:

Why does my clear coat have always a orange peal when applied over Ink Black? My other powders looks nice and smooth but when coating ink black with a clear coat I end up with a very heavy orange peal.

03/14/20 08:38 am

Answer:

Clear Coats including our Clear Vision PPS-2974 can magnify problems underneath especially when applied over a dark color like Ink Black PSS-0106.

Each coating you should be striving for a 2-3 mil thickness (.002"-003" thousandths of an inch or 50-76 micron). Too thin and your coating could have a tight patterned bumpy orange peal look and too heavy and you will have a wider spread orange peal. Often times Orange Peal will appear even when the coating is applied at the correct thickness but will smooth out at the end of the cure cycle. So, if you pull the part before the cure cycle is complete you may still see Orange Peal that could have smoothed out if the powder was allowed to complete its cure cycle. Cure timer should never begin until the thickest part of the substrate reaches cure temperature.

Orange Peal can be highly visible on a color like Ink Black (vs. a light base coat). If you apply your Clear Vision PPS-2974 over an Orange Pealed Ink Black, this will magnify the Ink Black's Orange Peal. Orange Peal can also appear in a heavy application of Clear Vision.

A mil gauge is an important tool to make sure you are reaching the proper thickness for each coating. This can be checked at the flow-out stage. Pull the part from the oven, allow to cool (below 120 deg F) and check thickness. If too thin then add more and re-flow into the original coating application.

Our mil gauge is an excellent buy.

Question:

Will this color work well as a coating for a motorcycle exhaust pipe?

07/14/19 09:17 pm

Answer:

Generally, no. Exhaust components generally get too hot for what traditional powder coatings can handle. The max temp powder coating can handle is about 250F with spikes up to 350-400.

For high temp coatings for exhaust we would recommend Cerakote's high temp line.

Knowledge Base FAQ

Added To Cart

Some powders may require either a base coat or a top coat or have other

special instructions. Please read each product description carefully to

ensure you are ordering what you need.

Amount: $0 /ea

Quantity: 1